Thermal Imaging and Preventative Maintenance Services

We can't all see the hidden issues, that's why it is important to include Thermal Scanning into your maintenance programs. Any faults on your Electrical system and plant can cause costly unplanned downtime. Thermal Scanning can help identify these issues before they become a problem.

Our trained and insured professionals can assist with your Thermal Imaging needs in Brisbane and where ever else your plant and equipment may be. Having our very own Flir T540 gives us the advantage of being able to provide our customers this service 24/7.

Plant and Equipment

The ability to plan your shutdowns to maximise repairs and reduce downtime.

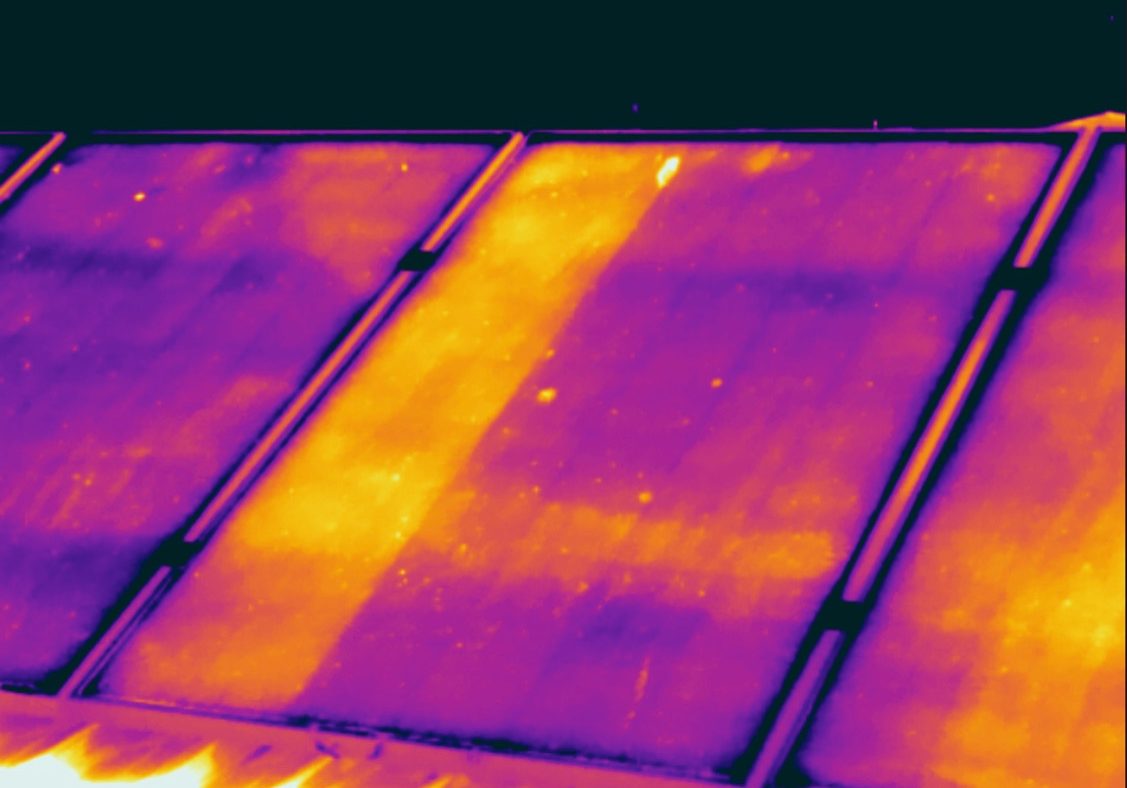

Solar Panels

Inspections on your solar system will help identify problem panels and reduce the risk of fire.

Control Panels

Identify potential equipment/ component failure or irregularities in loading.

Electrical Thermal Inspections

To thoroughly inspect your Electrical and Mechanical Services switchboards, escutcheons and covers should be removed exposing the wiring, busbars and components. This way a more detailed report specifying abnormallities can be found, resulting in savings of component failure and prevent fires caused by high temperatures by loose connections.

Mechanical Services Inspections

While Thermal Imaging is great for checking electrical connections and components, it is also fanatastic for checking your mechincal equipment for wearing/ failed components such as bearings in motors, rollers for conveyor belts and to notify you and your employees when it is safe to approach large plant equipment such as Haul Trucks when tyres generate too much heat in them. There are many ways Thermal Imaging can help support your business and equipment.

Benefits of Thermal Imaging

While we have devices that can detect fires, arc faults etc, there is nothing more effective than Thermal Imaging that can see the faults before they become visable.

By including Thermail Imaging in your maintenance schedule or even your pre shutdown inspections, you can:

- Pinpoint the specific component or problem area thereby minimising repair times.

- Eliminate unexpected plant and equipment failure.

- Immediately detect potential issues with wiring, switchboards and other electrical components.

- Comply with your insurance requirements for annual inspections.

- Reduce the risk of fires caused by electrical faults.

- Check component integrity.

- Go above and beyond your WHS measures and boost compliance with your regulatory requirements.